Unit 4, 7th Floor, Standard Factory B, Tan Thuan Export Processing Zone, Tan Thuan Street

District 7, HCM City, Vietnam

Unit 4, 7th Floor, Standard Factory B, Tan Thuan Export Processing Zone, Tan Thuan Street

District 7, HCM City, Vietnam

Describe your system/machine/project. What is the function of your application? Where is your application used?

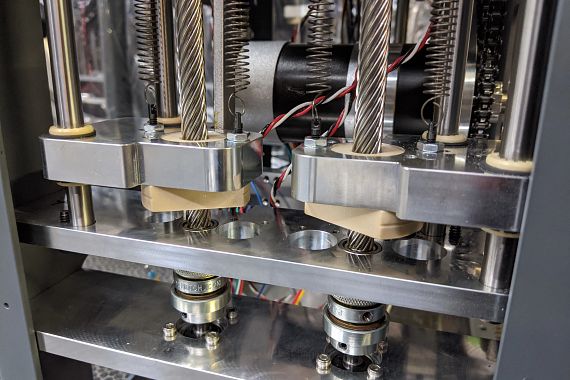

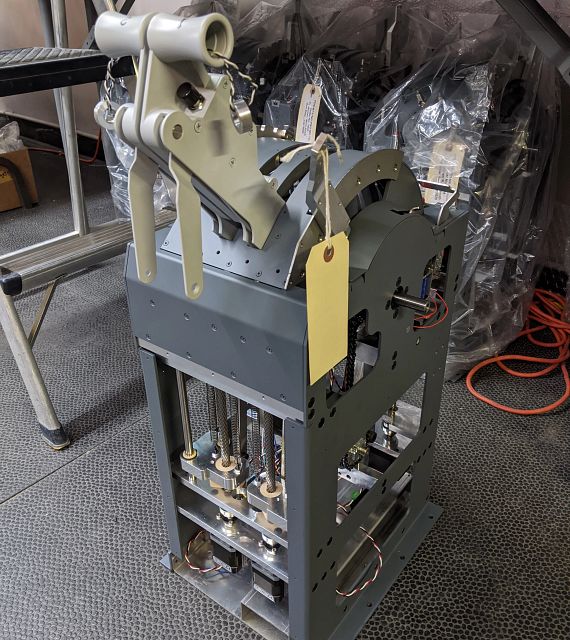

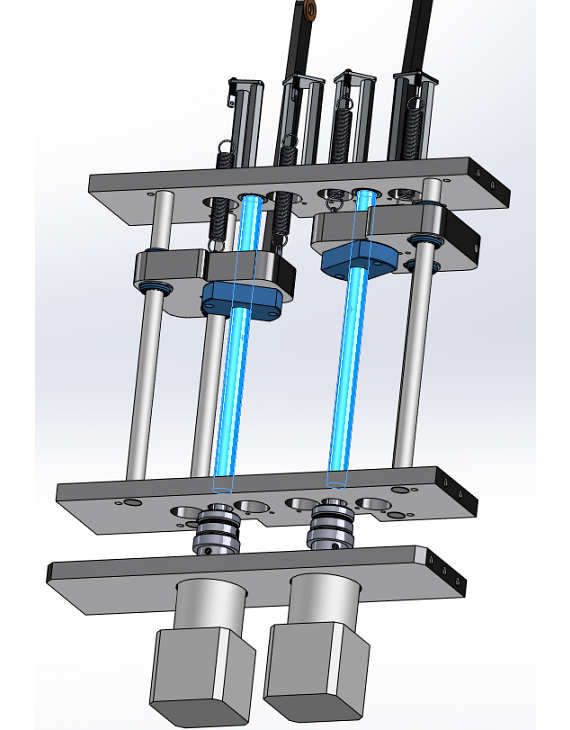

Our application is a simulated throttle valve for simulated 737 NG and 737MAX aircraft. The high-pitch lead screws we selected are used to replicate the auto-throttle system in the real aircraft. This system allows the autopilot to move the throttle automatically to control airspeed. Manual control can be assumed when the automatic throttle is deactivated. There can also be a manual override if the automatic throttle is activated, but manual control is still required.

What are the environmental conditions at the end user's location? What challenges did you have to overcome to adapt to those conditions?

The environmental conditions are typical indoor conditions worldwide. The system can be used in very hot and humid places and very cold and dry areas. The biggest challenge in recreating the automatic accelerator pedal system was to make it smaller while maintaining full functionality. The real aircraft system is connected with cables that run throughout the aircraft. We had to put the whole system into the part of the throttle above the floor. The next major challenge was designing a system that would allow both automatic and manual throttle control and manual override of the automatic throttle system.

What requirements did the lead screw drives have to meet?

The lead screws and lead screw nuts had to be robust enough to be used in all climate zones long term. And they had to be driven in reverse so pilots could override the automatic throttle system and control the throttle valve manually.

What alternatives to lead screw drives were considered?

We considered such options as belt drives, standard bronze-lead nuts, and direct servo drive. They were all either too big, too expensive or couldn't be adequately driven in reverse.

Which polymer bearing technology solutions do you use?

We used the dryspin high helix lead screws and lead screw nuts with 50mm pitch supported by 3/8" igus high-precision linear bearings.