Unit 4, 7th Floor, Standard Factory B, Tan Thuan Export Processing Zone, Tan Thuan Street

District 7, HCM City, Vietnam

Unit 4, 7th Floor, Standard Factory B, Tan Thuan Export Processing Zone, Tan Thuan Street

District 7, HCM City, Vietnam

Developing compact passenger doors for new light-rail vehicles on the Metro del Valles line in Barcelona is the job of Masats, a Spanish company. Engineers used igus chainflex control cables and e-chains in the door opening mechanisms. The special control cable design allows extremely small bend radii (just 20 millimetres). The cables are thus ideal for passenger doors that are among the most space-saving systems on the market.

The IdeasTrain is an initiative of Deutsche Bahn dedicated to tomorrow's passenger transport. One of the concepts developed here: an e-scooter lift for space-saving suspension and charging of the scooters during the train journey. The two-wheelers are hooked into a bracket and can be moved up and down electrically on a linear axis. This is where drylin linear systems and drives for lubrication-free operation come into play.

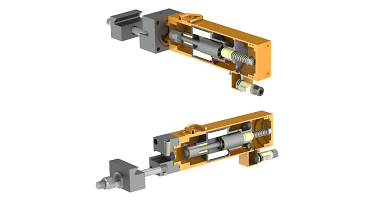

Sliding steps must work in all weather and be safe, so that even passengers with prams or limited mobility can get on and off without assistance. Lubrication-free and thus maintenance-free dryspin high helix lead screws and nuts from igus are central components of an innovation from Knorr-Bremse GmbH, Division IFE. They are resistant to corrosion and media and ensure a long service life ‒ at significantly reduced costs.

These high-speed trains travel between Beijing and Shanghai at speeds of up to 350km/h. The outer doors are guided with shaft guides from the drylin R series. The advantage: the liners of the linear bearings are made of lubrication-free and maintenance-free iglidur. In addition, the bearings move particularly quietly and work reliably even in the sometimes adverse weather conditions.

The train washing plant belonging to the Société Nationale des Chemins de Fer Luxembourgeois (CFL) cleans local and long-distance trains daily in its 200 metre-long wash hall. To allow the wash trolleys to travel on both sides of a train, several energy chains are used with intelligent sensor technology that monitors the plant condition and plans maintenance predictively.

This traverser in the harbour of Felixstowe in England ensures that the locomotives can quickly reach the correct one of the eight tracks. Locomotives weighing up to 170 tonnes are pushed over a distance of up to 30 metres. To guide the cables safely and reliably from the control unit to the traverser, even in the extreme weather conditions and harsh environments, and to keep the maintenance time to the minimum, the operators opted for an igus® flizz® system. This is made of stainless steel in which an E4 series e-chain® and chainflex® cables are used.

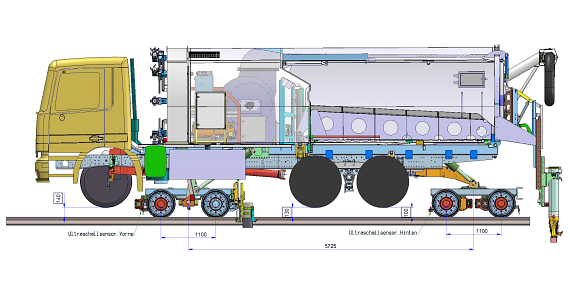

For the metro in Riyadh, Saudi Arabia, Zweiweg International developed a two-way cleaning vehicle featuring especially flexible cleaning technology. Linear systems from our modular construction kit also contribute to this technology. The linear technology, which requires no lubrication or maintenance, is compact when retracted, but allows for a long extension that does not yield too much under the high water pressure. Since it is lubrication-free, dirt and dust do not affect its functionality.